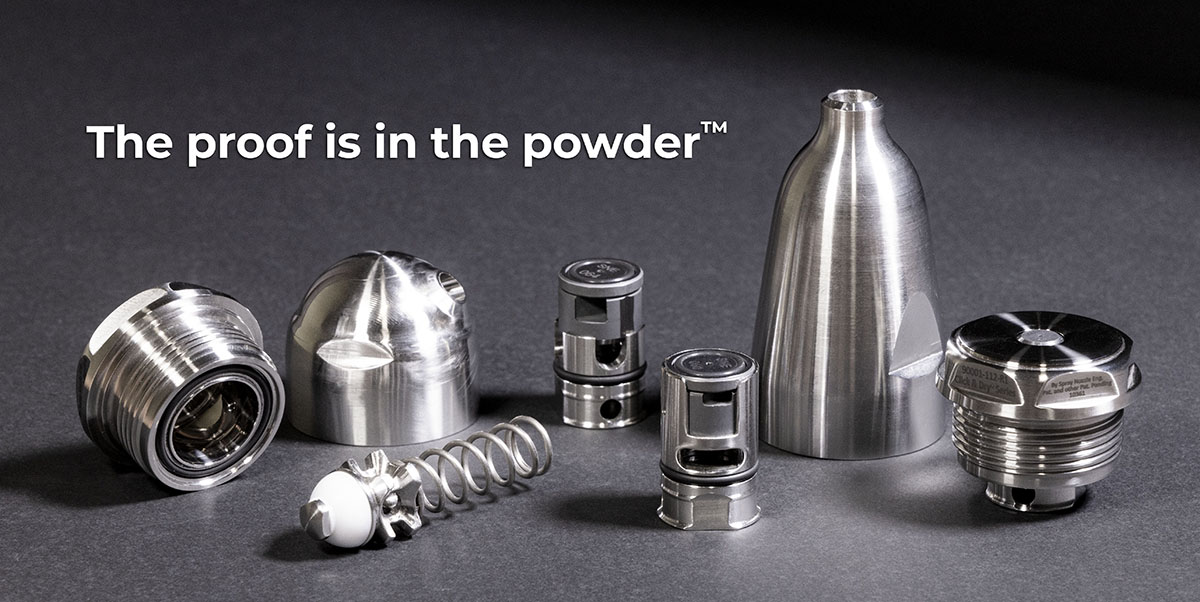

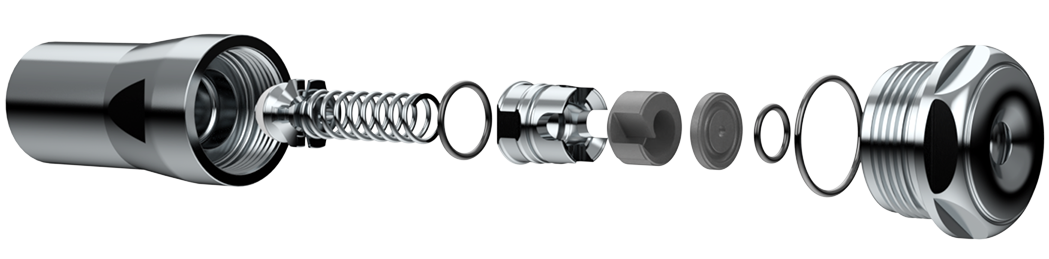

PLANT PROFIT: With our advancements in consistency, assembly logic and wear part life, you’ll easily see the results in your plant's profits.

Learn why CLICK&DRY™ Spray Dry Nozzles can easily increase your Plant Profit:At the end of the day, plant profitability is the most critical factor to consider. It's why all businesses exist in the first place, and we make no exception. Out of the various reasons why Click&Dry was invented, increasing any given spray drying facility's profitability was a significant issue. This remains a core concern for us to this day.